We consult with your team to assess your machine health problems. We then work with your machine experts to develop new health indicators, and if necessary, define and recommend new sensors with connectivity for your control environment.

Unlike traditional condition monitoring solutions, we specialize in developing health indicators based on an analysis of your machine in context, often with data from existing control instrumentation, so initiating a pilot study with available data is a great way to launch and accelerate the development of your CBM program.

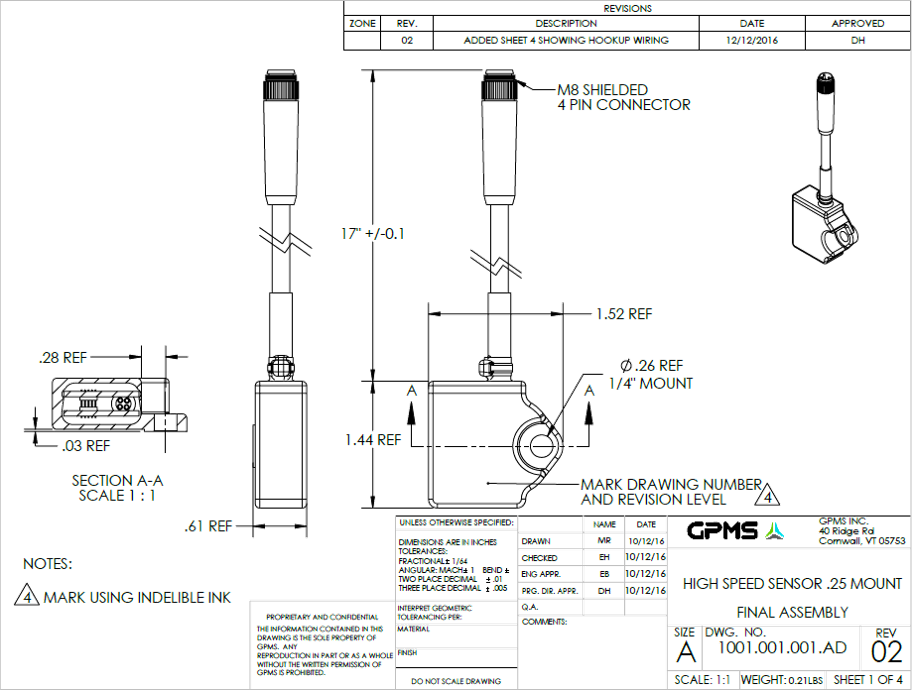

If additional data will be useful, we will recommend Data Acquisition (DAQ) solutions to collect and analyze the data, then define, design and build new sensors as needed.

Finally, we can also recommend deployable monitoring systems, with monitoring software and services.

Recommend condition monitoring systems

Data engineering new health indicators

Custom sensors developed as required

Provide monitoring software & services